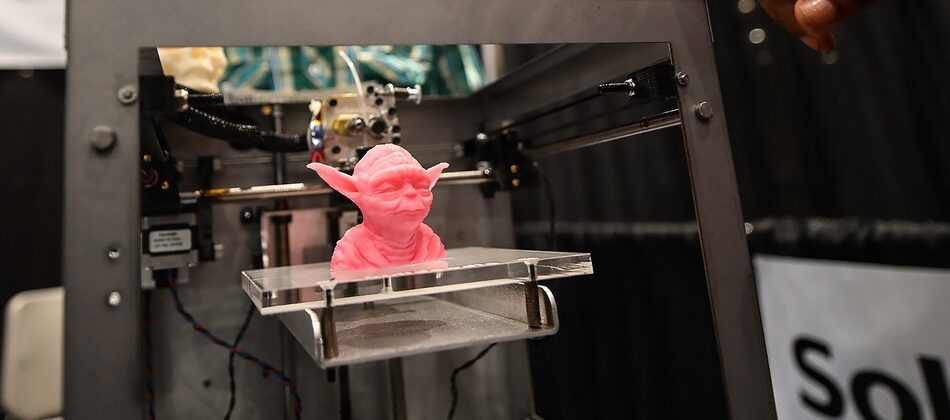

The current public debate about automation is a highly politicised one. The prospect of having your takeaway sushi dropped onto your roof terrace by a drone or to 3D print a custom made hip-bone is celebrated by the metropolitan professional class. At the same time they see a looming apocalyptic side of automation: the uneducated working class feels increasingly threatened by their robotic competitors and will therefore lose all liberal attitudes that ties them to the progressive world. Workers voted for Trump and other populists because of their fear that they can’t keep up with an ever faster, changing world.

The radical left is not very helpful when it comes to critically assessing the current discourse around automation from a working class perspective. Many comrades don’t question the hype. They believe that automation will kill off most manual jobs within the next decade or so. Based on this rather unfounded assumption, they are then forced to instinctively choose between two different camps: an affirmative camp (accelerationism, full communism: the robots will free us from work and we can live in luxury on dole money) or a nihilistic one (surplus population, external insurrection: everyone will be unemployed, angry and smash everything). But in order to be able to demystify the seemingly ‘automatic’ power of capital, working class analysis of current changes in technology will have to start from the bottom up. We hope that this article can contribute to this effort.

This report contrasts the experience of working in a 3D-printer manufacturing plant in west London with the general hype of ‘factory-less’ production and full-automation attached to this technology. In the first part we raise more general questions regarding the role of manufacturing or industrial production in capitalism and how the current debate about new technologies like 3D-printing is ideologically charged: with the capitalist zeal to cover up the contradictions of mass production and, with it, the essential core of capitalist exploitation. 3D-printing and ‘desktop manufacturing’ is portrayed as a symbol of revitalisation of the entrepreneurial spirit and of a utopia of small independent producers who engage freely on the market. In the second part we describe the production process and working conditions in the manufacturing plant. We don’t write these reports as an academic exercise, but as part of our proletarian research and intervention in west London.

For some pretty random shots from within the plant – check out our art corner. [1]

1) Be your own factory – Artisan dreams and capitalist production in the era of 3D-printing

Before we engage with the hype and reality of current production technology, we want to take a step back and look at the relationship between industrial or mass production and capitalism, and the contradictions within. Our political focus on industry is due less to a nostalgia for the old, blue-collar working class and their militancy, but to the search for the inner constitution and weaknesses of capitalist exploitation.

* Historically the social power of capital was based on the ability to confront the artisans and small producers with a) a global supply-chain of new raw materials (cotton from US plantations etc.) founded on slave labour and b) an industrial system that transferred individual skills onto an apparatus (machinery) that allowed productivity to increase through combining the labour of many workers (division of labour). Capital therefore appeared as the precondition of social (re-)production in two ways: as the force that connects plantations in the south with factories and markets in the north and as the force that brings individuals of various social backgrounds together to cooperate under its supervision and thereby increasing the productive potentials of human activity to unprecedented levels. When we say that capital appears as the precondition, we mean that it is only under capitalist command that workers can get together with the products of former labour necessary to produce: raw materials, machinery, knowledge etc..

* The foundation of capitalist domination is the expansion of machinery and cooperation in order to a) impress individual workers with their own dependency on capital in order to set the production process in motion and b) to contain the discontent of the emerging working class by expanding not only machinery and state repressive apparatus, but also working class consumption. We can see that ‘economies of scale’ and ‘mass production’ is neither just a ‘technical requirement’ (some people claim that steam engines ‘technically’ required large scale factory organisation, in order to make efficient use of them) nor just a ‘more rational way of doing things’. ‘Economies of scale’ are the surface apparition of the contradiction of the capitalist mode of production: the necessity to dominate the working class by surrounding – and replacing – them with machines on one side, and on the other, capital’s dependence on living labour and workers’ cooperation for valorisation.

* The contradictions of mass production are obvious. A relatively larger share of investment is tied up in machinery, which forces capital to utilise it permanently and churn out products even though markets are saturated, creating regular situations of over-production. Although capitalism’s main legitimacy is that it is supposed to promote ‘free wage labour’, ‘free markets for producers and consumers’ and ‘democratic citizenship’, the industrial system is intrinsically based on brutal domination and oppression of individual freedom and it leads to monopolies, which undermine the ideology of equality on the market.

* Unsurprisingly, one of the earliest criticisms of capitalism and its blatant contradictions was raised from an artisan point of view, re-claiming the original promises of capitalism: instead of big industry we should have a network of small artisan producers and instead of big finance we should establish new forms of money for direct exchange (Proudhon etc.). Although conservative at its core, this criticism retained its appeal because it took capitalism’s ideals at face value. Time and again the representatives of capital have to make use of it themselves: to encourage entrepreneurial spirit and individual skills.

* The reaction to the working class struggles in the 1960s and 70s, which criticised the factory and assembly line-based work both from within (slow-downs, sabotage, coordinated department strikes etc.) and without (criticism of consumer society), was not only repressive e.g. in the form of factory closures and mass redundancies. Capital had to develop a ‘new promise’, the promise to overcome the monotony of industrial labour and the awkward realties of environmentally harmful over-production. In the 1980s we see two intertwined and mutually dependent phenomena: the over-represented reality of robotic or automated production and the announced return of small-scale production networks. Robots were supposed to take over the monotonous mass work, whereas small-scale production would make jobs more interesting and capitalist production more in tune with markets, consumer needs and nature.

* We can find a lot of representatives of these post-Fordist ideologies: the so-called ‘flexible specialisation’ of Piore and Sabel promised to solve many of capital’s problems; representatives of capital announced that the textile industry in northern Italy was finally based on egalitarian production networks and had overcome the uneasy constraints of the ’economy of scale’ (Benetton model); and even the global car industry competed in promotions of ‘team-work’ and ‘job enrichment’ (Toyotism). We have to bear in mind that these ‘libertarian’ ideologies circulated at a time when capital launched its full-blown attack on the remaining industrial strongholds of workers’ power in the global north.

* Unfortunately large parts of the left allowed themselves to be blinded by both phenomena: either staring into the headlights of a robotic dystopia or believing the hype of a future post-Fordist network of free producers. This was partly because of their lack of historical and theoretical understanding of capitalist value production and its’ contradictions, and partly because of a lack of empirical experiences and research into the actual day-to-day application of technology within the production process.

* The development of micro-electronics and logistical infrastructure since the 1980s has changed the production process, but hasn’t led to either a massive increase in automation or the establishment of networks of small-scale enterprises. Relocation of production and increased unemployment depressed wages in the global North, which hampered the investment in armies of robots. The internet didn’t lead to de-centralised networks of production and distribution, but created the pyramids of Amazon and Uber. Although desktop computers and telephones could have meant that people work from home, we saw the massive proliferation of large-scale call centres instead. Direct control over workers and direct cooperation by workers seems to outweigh the higher investment costs. Similarly, garments are rarely produced within a ‘productive network’ of small producers in the Veneto, but in mass factories in Bangladesh. The automobile industry and mobile phone industry depends heavily on the supply of a handful of major global suppliers and the 8,000 DHL workers who operate within UK car factories doing former ‘manufacturing workers jobs’ (moving parts within the plant) are statistically categorised as industrial service workers. While everyone stares at the automatic GPS-controlled cranes of modern ports, biding a melancholic farewell to the old dock workers and ‘manual labour’, there are 300,000 UK warehouse workers unloading the containers in the invisible hinterland.

* Currently we face a similar situation to the first ‘automation’-hype during the early 1980s. The crash in 2008 revealed the extent of production over-capacities that couldn’t just be smoothly switched off once the market demanded less – while factory struggles in China and workers’ struggles in new concentrations such as Amazon warehouses showed that the internal antagonism to mass production has not been overcome. Given these objective and subjective constraints on capital it is not surprising that despite historically low rates of productive investment the media is full of news about the ‘robot wars’ and the threat of automation. Having been cornered by the crisis and seen their legitimacy going down the drain, the representatives of capital need a both enticing and menacing scenario. The labour-replacing robot or drone is contrasted by another prevalent idea: that of the artisanal utopia that the ‘internet of things’ and ‘open source’ technology can lead us towards a ‘sharing economy’.

* Contemporary ‘free market anarchists’ (Carson, P2P-Foundation, Commons Transition etc.) [2] affirm capitalist ideology of the libertarian qualities of market relations. They assume that ‘big industry’ was only more productive due to ‘state suppression’ of free competition (subsidies of patents and monopolies). Their nostalgia for the ‘artisan mode of small scale production’ idealises its origin: the heavy legal and patriarchal intervention when it came to the question of who was allowed to become a ‘free artisan’ and who not. Their utopia is inward-looking, afraid of the global dimension of capitalist society – and of the productive force of (global) industrial cooperation of workers, which they don’t understand.

* As one example, the mainstream prognosis of the impact that 3D-printing will have on manufacturing is similarly two-faced: a) 3D-printing will finish off mass production (workers) and logistical nightmares by customised print on demand and b) we will all share our .stl-files with each other and we all can be producers and consumers at the same time, owning our own means of production. The entrepreneurial spirit still claims that despite new populist despotisms, global wars and Walmart/Google-type of monopolies, a clever ‘invention’ such as 3D-printing can revive not only the sphere of small producers on an egalitarian market, but through ‘democratisation’ of industries will also reclaim our liberties as citizens. The middle-class left that is still clinging onto neoliberal ideas of ‘immaterial labour’ involuntarily or not takes part in this process of mystification. We repeat: to overcome ‘economies of scale’ or an ‘industrial form of production’, it would not merely require technological change, but a fundamental change in the form of exploitation and political domination beyond its capitalist form.

* It is true that the contrast between the potential of technology and knowledge to guarantee a better life for everyone on one side and the reality of most people on this planet on the other side is the main revolutionary explosive within capitalism – to point this out does not let us off the hook to analyse the relation between workers and machinery in detail. What we need more than ever in order to find our bearings is, to speak in awkwardly orthodox terms, a value and use value analysis of the contemporary use of capitalist technology. Meaning, a) to analyse how the current ratio between wages, profits and cost of machinery (value side) determines the investment into machinery and where and how new machinery is applied or not; and b) to actually observe the material process and impact of technology once it is operated by workers: how does the division of labour and relationships amongst workers change, the knowledge of individual workers and the wider workforce, the ability of the bosses to control the production process and the potential for workers to subvert the new technology and appropriate their potentially ‘revolutionary’ characteristics. When it comes to the ‘material world’ and efforts to understand its working unfortunately even bourgeois journalism tends to be ahead of (radical-)left critique. [3]

In the following we first have a look at the ‘ideological’ side of 3D-printing, looking at how the technology and its potential social impact is portrayed. We contrast this with the first apparent contradictions, e.g. in terms of ‘open source hardware’ vs. corporate profit needs. We then point out some of the current financial and technical problems that still prevent a mass scale application of 3D-printing in manufacturing. We finally share our experience of both using the technology as consumers and producing the machines as low-paid workers.

* The hype

We want to contrast a quote from a text written in the early 1990s on the contemporary hype of ‘post-Fordism’ and ‘flexible specialisation’ during the period of proliferation of computer technology with the way that the potential impact of 3D-printing is portrayed today.

“The system of mass production has reached its limits (Storper, 1989). Piore and Sabel (1984) and Best (1990) have convincingly argued that there are alternatives, however. The alternative is producing smaller series of specially designed goods of a specific quality for a niche market, which may command a higher price. Piore and SabeI (1984) argue that the history of industrialization has held open one major alternative to the system of mass production, namely craft production, based on the flexible use of general purpose machinery by skilled workers, capable of manufacturing a wide range of products for constantly changing markets. Increasingly segmented markets forced enterprises to follow a strategic approach and to go for specialisation and flexibility.”

As we pointed out, since this text was written we have seen the development of further concentration within the automobile industry (single export factories of a ‘world car’, instead of custom-made cars ‘on demand’) and large concentration processes in electronic goods (Foxconn etc.) and retail (Amazon etc.). Bearing this in mind we can read about 3D-printing 25 years later:

“Who would have thought that modern manufacturing could be done without a factory? Since the Industrial Revolution, manufacturing has been synonymous with factories, machine tools, production lines and economies of scale. So it is startling to think about manufacturing without tooling, assembly lines or supply chains. However, this is exactly what is happening as 3D printing reaches individuals, small businesses and corporate departments.”

“It is not hard to imagine a future factory that can manufacture tea cups, automotive components and bespoke medical products all in the same facility via rows of 3D printers. Flexibility to build a wide range of products, coupled with the fact that 3D printing can be done near the point of consumption, implies a serious change to supply chains and business models. Many steps in the supply chain can potentially be eliminated, including distribution, warehousing and retail.”

“3-D Printing: The Democratization of Manufacturing – Will “3-D printing” technology come to the aid of the West and destroy plutocratic capitalism’s plans to deindustrialize western nations? The real meaning of this technology lies in the fact that it grants individuals the ability to manufacture consumer goods at home. This in turn might spell the end of the “outsourcing” mania which has destroyed most western industry.”

The left and not so radical left takes part in this hype e.g. in ‘Capital&Class’ we can read:

“The technical division of labour in capitalist enterprises constitutes the geometry of the labour process. It situates each moment of the labour process in a particular place. In 3D printing, this geometry is replaced with successive algorithmically guided movements of the printer’s nozzle. Hence, 3D printing holds the potential to abolish the factory regime altogether. Generalised 3D printing also abolishes the market. The social division of labour, which is the sum of different branches of production producing different goods, is also transcended.”

Meanwhile, the ‘free market anarchists’ write in “The Homebrew Industrial Revolution”:

“‘The tools of factory production, from electronics assembly to 3D-printing, are now available to individuals, in batches as small as a single unit. Anybody with an idea and a little expertise can set assembly lines in China into motion with nothing more than a keystroke on their laptop. A few days later a prototype will be at their door , and once it all checks out, they can push a few more buttons and be in full production, making hundreds, thousands more’”. […] The distinction […] between worker and owner is being eroded.”

* What is 3D printing?

Various different processes are lumped together under the term 3D printing. What they all have in common is that a picture is created with the help of a computer and CAD software, which is then transformed into a three dimensional object. This is done by adding material, rather than by subtracting it (like CNC milling etc.) or by injecting it into a mould (traditional plastic manufacturing). The differences in how this transformation takes place are quite fundamental.

The most basic way is to heat up (plastic, glue-based) material and extrude it through a nozzle. The nozzle is attached to an apparatus similar to a normal 2D ink-jet printer, just that it moves up and down, as well. The material is put on layer over layer. The technology is not substantially different from ink-jet printing, it only requires slightly more powerful computing electronics and a material with the right melting and extrusion qualities. This is the cheapest way to print 3D objects. Printers can be bought for £200 and less. The two other main methods of 3D-printing are fundamentally different.

The second method (SLA) uses UV light/laser to project the picture of a single layer onto a resin liquid (photopolymers). Because photopolymers are photosensitive under ultraviolet light, the resin is solidified and forms a single layer of the desired 3D object. This process is repeated for each layer of the design until the 3D object is complete. This process is faster than the ‘extrusion method’ and the layers stick together more solidly. The disadvantage though is that the liquid nature of the raw material makes printing certain shapes more difficult. The printers tend to be more expensive, too.

The third method is almost exclusively used in commercial and industrial set-ups. Selective laser sintering (SLS) uses a laser as the power source to sinter or melt powdered material (typically metal, ceramics), aiming the laser automatically at points in space defined by a 3D model, binding the material together to create a solid structure. Decent industrial printers cost £100,000 plus.

Like with any other ‘invention’ it is difficult to reconstruct the technological history of 3D-printing. Let’s look at the common views on how things are ‘invented’ or developed:

a) the defenders of the market economy want to make us believe that technical development is largely ‘consumer driven’: people develop new needs and the industry reacts to satisfy them

b) if not based on new consumption patterns, they claim that some entrepreneurial genius had great innovative ideas in his tinpot garage lab and then made big money by becoming a manufacturer

c) a significant minority of people claim that any major technical development originated in the military complex or its state funded science sector

d) our traditional view is that ‘inventions’ are appropriated workers’ knowledge: engineers and so-called scientists observe the problems within the production process and how workers cope or don’t cope with them and then appropriate this information as building blocks for their ‘technical discovery’.

We don’t know much about the exact development of 3D printing. The official version is obviously attached to some MIT labs and patents. Others claim that there was only a leap in ‘grassroots’ experimentation once the basic 3D-computing software went open-source. People started to build their 3D printer kits at home and exchanged their experiences online – on a very basic level, due to small capital investment. Big industry started to use 3D printing early on – instead of building car or aerospace part prototype models out of foam or clay or wire, 3D printing allowed more accurate and quicker modelling. Although perhaps not representative of the entire industry, looking at how 3D printers were developed (and by who) in the manufacturing plant in London might give some clues – see report in the second part.

* Current application and industry

Currently 3D printing represents only 0.04% of the global manufacturing market – meaning that only few parts or items that are manufactured are 3D-printed. (Industrial) prototyping of new products is the largest commercial application for 3D printing today, estimated to be 70% of the 3D printing market. In this sense 3D printers are rather used as a (designing) tool, rather than as machines. But then there are specific sectors – usually requiring items that have to be custom-made or are not manufactured in large quantities – where 3D printing plays a bigger role. This mainly includes more expensive art/fashion sector and medical industries, e.g. 98% of hearing aids worldwide are manufactured using 3D printing, so are many dental replacements. Obviously there are no limits to imagination:

“Cornell University, working with the French Culinary Institute in New York, took the idea further by creating a range of 3D-printed food items such as miniature space shuttles made of ground scallops and cheese.”

“In another application, the silver ink has been printed onto three-dimensional surfaces to create small electrical antennas that perform an order-of-magnitude better than traditional antenna designs. These antennas show potential for implantable or wearable antennas, sensors and electronics.”

“Contour Crafting proposes 3D printing an entire house, targeting low-cost and emergency housing (after a natural disaster, for example). The company claims an entire 2,500-square-foot home can be built in 20 hours (doors and windows added later) with extremely large 3D printers and specially formulated concrete.”

The following quote is a great example of the stark contrast between the potential of the technology and the reality of its application under the current system. Anyone who knows a bit about the anti-working class racist politics of the US state after Hurricane Katerina will understand what we mean:

“A quite different military application of 3D printing is the creation of topographical models to provide better intelligence. The U.S. Army Corps of Engineers used this technique when responding to Hurricane Katrina. The Corps generated and regenerated models of New Orleans as the situation evolved. The models, which could be created in about two hours, showed changing floodwater levels, buildings and other features of the area. This aided in situational understanding and helped guide the relief effort as soldiers and civil authorities worked to save people and property [sic!].”

(3D Printing and the Future of Manufacturing – CSC LEADING EDGE FORUM)

We will discuss the current technical and financial reasons for the limited use of 3D printers as means of production later. The market for 3D printers as means of consumption, for use as a non-commercial home appliance, might develop faster. Of the roughly 240,000 3D printers sold in 2015 over 90% were cheaper ‘non-industrial’ extrusion printers. The market is still dominated by a variety of small companies selling around 20,000 per year and less. This compares to annual sales figures of, e.g HP inkjet/laser 2D printers of 42 million or 22 million by Canon. These companies have not seriously invested in 3D printer manufacturing yet, partly given the still small volumes, partly because of immature technology.

* Current technical limits to mass application

Leaving aside questions of profitability for the moment, there are some technical problems which, up until now, have prevented the mass application of 3D printing beyond prototyping (meaning the printing of models, jigs, tools or moulds for later use in traditional production methods, such as plastic injection moulding). Some of the advantages of 3D printing compared to CNC milling or plastic injection moulding are obvious: it is easier to change and adjust objects when using computerised 3D designs; you can print more complex structures compared to the objects you would get from moulding or die casting; you have less wastage printing than from shaping the object through milling. But there are less obvious disadvantages:

* Precision is a problem: Standard tolerances for CNC machined parts are +/- 0.005” or 0.001”/”. 3D printed tolerances vary but are generally in the +/-0.009-.020” range.

* CNC (metal) milling and (plastic) injection moulding have a smoother surface finish, which is not just an aesthetic issue, but of functional importance if the part is used in a bigger mechanical system. Most 3D-printed parts would require extra labour to achieve a similarly smooth surface, using acetone and other nasty chemicals.

* 3D-printed parts are weaker, they usually have 1/3 of the strength of milled or moulded products. In something like injection moulding or CNC milling, you have a very even strength across the part, as the material is of a relatively consistent material structure. 3D-printed parts are build in layers – this results in laminate weaknesses. This also means that 3D-printed prototypes can often not be used for physical tests, just for optical ones. The stronger-type plastics (G-10/FR4 (45,000 PSI) and FRP (30,000 PSI) cannot be used for 3D printing.

* Inconsistency of material structure within the part: for example a thin walled section created by laser sintering cools much slower than a thick section. This has an impact on the microstructure and therefore the mechanical properties of the material.

* The fact that a relatively low heat (around 90 Celsius) or UV light is used to form the plastics or resin liquid means that a finished part can’t be exposed to either heat or strong light if its quality is not supposed to be compromised.

* Bigger contamination with ultra-fine particles (UFPs), which is not necessarily the problem of the capitalist. Thermal extrusion of plastics by 3D printers emit a large amount of very small particles, mostly less than 100 nano metres in diameter, that can cause damage to lungs and other organs. Similarly the ‘powdering’ of metals for the laser-sintering process is pretty energy consuming and environmentally unfriendly.

* Current financial limits to mass application

The other main obstacle to using 3D printers for general manufacturing is production costs. While the process from design to creation of prototypes and small-scale models can be sped-up using 3D printers, their application in larger scale manufacturing is too expensive:

* The machinery itself is too expensive: a decent SLS 3D printer capable of processing metal still costs £100,000 plus, whereas a comparable CNC machine costs less than half the price.

* The raw materials tend to be more expensive, too: metals or ceramics have to be pulverised before being processed. At the current rate, the cost of plastic feed material used in 3D printing ranges from £40 to £80 per kilogram, while the equivalent amount of material used in traditional injection moulding is only around £2.

* 3D printers are significantly slower than traditional manufacturing methods: plastic injection moulding can produce around 1,400 parts per hour, more expensive SLA/CLIP printers (UV-Laser) print perhaps 8 to 10 parts per hour, while with an extruder printer it often takes several hours to print a small-sized (15cm X 15cm) object.

* The labour time to manually operate 3D printers (setting-up time, changing parts / feeding material, retracting finished products etc.) won’t be much different from operating traditional machines, apart from maybe tooling time (swapping tools for different sized objects or materials) – see experience below from our manufacturing plant in London.

Based on this, industrialists claim that for production series bigger than 1,000 pieces, traditional manufacturing methods will be more cost effective. 3D-printed, most goods that we buy or consume would become too expensive for us to afford them. The question remains whether 3D printing can change the production process qualitatively, so that overall less labour input is required.

* The operation of computer software to create designs won’t differ too much, whether you create designs for 3D printing or CNC milling. What is likely to happen with the expansion of 3D printers as a means of consumption is the proliferation of knowledge about these programs. People would learn about basic CAD programs at home, in their free time. The application might be limited: to design a simple spoon with a simple program from scratch still takes a day or two – while you can buy a perfectly fine plastic spoon for 1p in your nearest pound-shop.

* More substantially would be if 3D printing could minimise assembly work by printing mechanical systems composed of separate parts or by replacing moving parts with different types of structures. Some companies boast of 3D-printed useable full-plastic adjustable spanners, which would have had to be assembled using traditional methods. Problem here is that most assembled objects in our daily life are made up of different materials and given that 3D printing operates with heat and that different materials are processed at very different temperatures, it seems unlikely that 3D printing will replace assembly operations in the near future. There are 3D-printed one-piece full-plastic door latches including door handle around – they don’t have mechanically moving parts, but the latch is moved by twisting a honey-comb structured core – a so-called meta-material. Doesn’t look too revolutionary yet either…

In this sense what looks most likely for the near future is that you might 3D print a custom-made mobile phone cover for your mass produced Iphone or a hand-scanned gear-knob for your second-hand Audi A4…

* What about communism? – looking at the Open Source reality

We don’t want to be party-poopers and just talk about mundane things like per-unit costs and advantages of injection moulding. There is something ‘communist’ about 3D printing: people all over the globe can throw their ideas together, share problems and solutions and transform their collaboration locally into useful or playful objects. This is not an artisanal mode of production based on individual skills, which can only be shared personally with a limited number of people and only over a long period of time. Potentially this is not industrial production, with a huge gap between the engineers and the manual labourers and a clear separation between producers and passive consumers of indifferent mass products. We don’t have to get our hands (too) dirty, instead we use our collective brain – whose products can be copied and shared without much effort. There is a potentially new quality in this technology, which could be appropriated by new social relations. Will this happen gradually – in the form of proliferation of open source and communal tech labs? Or will it require a deeper rupture with property and power relations?

* We see the proliferation of ‘open source networks’ around 3D printing as an expression of two conflicting tendencies:

a) the fact that there is a new ‘grassroots’ quality about the technology; we never saw a similar emergence of networks of ’excited’ techno-enthusiasts who think together and share knowledge about their experimentations around, for example, CNC machines or power presses.

b) The fact that big businesses are not in there yet; it’s not that there is not a necessarily ‘democratic’ quality behind the appeals for ‘crowdfunding’ of innovative initiatives of 3D print projects, but simply a lack of venture capital. As we can see, the ‘entrepreneurial spirit’ that is attached to these creative networks quickly commercialises, last but not least under pressure from the state.

* Non-commercial initiatives attached to academia and the NGO sector such as RepRap (Replicating Rapid Prototyper) and FabLabs (Fabrication Laboratories, set up by MIT professors) are the official faces of the otherwise more diffuse 3D open source ‘community’. They produce open source hardware (printers) and software for the public or make them available. They harness collective innovative spirit (business analysts CSC note that the “rate of innovation of the RepRap and its derivatives is accelerating faster than equivalent commercial 3D printers.”) in an official framework, encouraging small entrepreneurship, e.g. the small-scale manufacturing of the printers themselves or ‘community businesses’ (“Habibi.works will be one of the newest FabLab to the list, and is expected to launch in November 2016. This remarkable lab will be set up in Northern Greece, and is giving refugees from around the world a chance to learn and share their skills alongside a local Greek community, in order to collaborate and improve the environment around them.). The line between these types of ‘grassroots enterprises’ and ‘start-up companies’ becomes blurry. An old friend of mine works in a FabLab in Germany and he told me that one of the current positions within the FabLab community is that people are encouraged to commercialise their inventions under the conditions that they keep things ‘open source’, meaning, making the technical documentation accessible to others. He used to work as an technician for a major German automobile company and according to his opinion the FabLab community – despite their ‘general intellect’ and horizontal networking – are years behind the research and development departments of major car manufacturers. This is mainly due to the fact that even very bright minds need material and instruments to transform ideas into things – and these things cost money.

* A financial bridge between ‘collective innovation’ and small-scale entrepreneurship is crowdfunding. “Although low-cost 3D printers and accessible CAD software lower barriers to entry for bringing new products to market, some capital is still required. This is where pioneering initiatives like Kickstarter come in. Kickstarter, a crowdfunding website for creative projects, allows anyone with a good idea to advertise for seed funding, usually provided by large numbers of small investors. The rewards for the investor are set by the entrepreneur and typically range from thank-you certificates for small donations to free copies of the product being sponsored.” As we have seen with micro-credit schemes for artisan and peasant projects in Asia, there is no such thing as ‘democratic money’: money changes social relations and ties us into the global ups-and-downs of commerce and finance.

* Many of the initial 3D printer manufacturers might have started as small garage projects, still materially and ideologically attached to their open source roots, but market relations sooner or later over-stretch these ties. One example is the company Makerbot – one of the main manufacturers of consumer 3D printers. They developed their first printer as part of an open source ‘crowd’ initiative, but closed the files during the development of the second generation as soon as business took off. Similarly, their online software platform for 3D printer designs ‘Thingiverse’ still appeals to the open source spirit, but is open only for people who have bought Makerbot hardware. They are dependent on more than just ‘crowdfunding: “Last year MakerBot raised $10 million from investors, including Amazon founder Jeff Bezos, to fund its expansion. It will need all that and more to compete with a host of other emerging low-cost 3D printers, including Chinese devices and emerging copycat clones.” Unsurprisingly, they accept the tightening grip of the (patent and copyright) law when it comes to their ‘crowd software platform’: having been threatened with the Digital Millennium Copyright Act 1998 (US) they removed the files of 3D-printable electronic designs (crafted by individuals) modelled on existing (commercial and patented) objects. [4] We can currently observe how commercial interests get in the way of social productivity and creativity, e.g. due to the fact that different companies promote different types of 3D design file formats or software hoping for competitive advantages, which hinders cooperation and communication in general.

* Unsurprisingly 3D printing is now at the heart of the legal dispute around copyrights, patents and intellectual property, though the conflict is still largely a proxy war. Recently Google and the Motion Picture Association of America (MPAA) got involved in lawsuits concerning the supposedly illegal importation of 3D-printable files, categorised as “articles”, rather than just data. While usually, objects were patented, now the army of corporate lawyers and pundits have to find ways to patent ‘methods of designing’ and find it increasingly difficult to pinpoint the original source of human creative expression. The contradictions that emerge once social creativity and social needs are subjected to the framework of ‘private property’ or company profits become apparent in legal disputes around patents, trademarks and copyrights. The critique of anti-copyright activists has to go deeper than just focusing on the obvious ‘betrayal’ by companies such as Makerbot or anti-piracy attacks by the law, but rather question the ‘entrepreneurial’ spirits and commercialised relationships which have roots in the open source movement itself. [5]

———

2) Manufacturing reality

Sources say that around 3 to 5.4 million people in the UK are employed in the manufacturing sector. As the following report about working in a 3D printer manufacturing and ink cartridge re-filling plant in London shows, a lot of industrial jobs today are at odds with the common (left) notion of factory work: the buildings are often unidentifiable as industrial workplaces, the official categorisation of the company might not be ‘manufacturing’, the workers themselves don’t wear oily blue collars, revealing hairy chests.

*** The company background

The company I worked for is located in the heart of Park Royal, formerly one of UK’s largest manufacturing zones in the west of London. Up until the late 1970s, workers in Park Royal produced London double-decker buses, parts for the automobile and aerospace industry. Things have changed since then. There are still around 28,000 workers employed in Park Royal, but potatoes and pallets have replaced sheet-metal and power presses: most people work in food processing plants and warehouses. Indeed, the area is now a ‘multiversum’ of small and medium sized companies, but it has little to do with the ‘productive horizontal clusters’ idealised by the post-fordist ideologues. From the outside the company looks like yet another nondescript 1980s warehouse space with office attachment. In the statistics the company will most likely appear as a ‘recycling service provider’. Its’ story is a good example of a modern start-up company, but instead on university drop-outs finding consensus business decisions on beanbags – probably the more common imagination of start-ups – it is based on low-waged female migrant labour, relying on a combination of proletarian inventiveness and low capital investment.

The founder of the company used to work as a manager for a major desktop-printer manufacturer. His entrepreneurial genius consisted of combining three economic sources of major significance in the UK – the charity sector, the big retail chains and migrant labour – and to give his enterprise an ecologically-friendly sheen. The company contacted major UK charities, asking them to pass on envelopes to their members and donors, who in turn were requested to send their empty ink cartridges to the company. The company would re-fill the cartridges, sell them to major retailers, such as WHSmith, and donate a small share of the profit back to the charities. The company hired mainly female workers, most of them originally from Gujarat, who, initially with primitive tools, re-filled the ink cartridges on minimum wages. Free raw material and a charitable, ecological reputation – who wouldn’t think that this a great start-up idea, but the Queen herself, who gave the company founder the ‘Queen’s Award for Enterprise’ in 2004. The company expanded, employing up to 250 people. Colleagues said that in their heyday they re-filled 15,000 cartridges a day. This is a pretty good productivity rate: the UK consumes around 45 million cartridges a year and with 250 people and basic machinery you can recycle around 4 million of them. While the company clocked £2 million profit per month, the wages of the workers did not increase. During the late 2000s the competition from re-filling factories based in China grew considerably, thanks to internet retail and logistics chains. By that time the upper-management had diverted a fair amount of business profits into real estate and kept the business ‘ticking over’ – the rounds of redundancies and spells of short-time work became more frequent. By the mid-2010s there were only 150 people left in the ink department. With the ink-cartridge department in slow decline, a new project was needed, last but not least in order to guarantee future bank credits. Making use of the ‘tech-bubble’ and the venture capital around it, management decided to branch out into 3D printer manufacturing.

They started collaborating with a 3D printer manufacturer in the Czech Republic, basically taking over their printer design and supply chain. By that time there were many different basic 3D printer kits available on the market, starting from £300 for unassembled kits. In order to distinguish themselves from other small-scale manufacturers, the company entered an agreement with another capitalist zombie we’ll call ‘Paranoid’. Paranoid came to great fame as an instant-photo-camera manufacturer in the 1980s, but went bust in the 1990s. Nowadays Paranoid basically makes money by selling their brand name to second-rate manufacturers of radios, video projectors and other electronic devices. Production in London could take off…

*** The 3D printer department workforce

The job as an assembly operative was advertised on the usual job sites. At the time I was working as a road sweeper and I thought it would be interesting to leap 10,000 years ahead in technological history and assemble 3D printers instead – modern proletarian minimum wage existence can be your personal Back to the Future trip. I had done assembly work before and had some soldering experience, which came in handy, but was no precondition as such. The company manager responsible for recruiting said that only “a dozen people applied and only five were suitable” – this low number of applicants will be mainly due to the low wage the company was offering for soldering and wiring work. When I started working, the department was just about to shift from the Czech Republic model to the new Paranoid outlook, which meant minor technical changes to the existing model, the addition of a web-cam and change to the colour scheme. Perhaps I should introduce some of my colleagues first:

I. grew up in Ireland, worked in the Netherlands as an agricultural labourer, then went to a technical college for two years, learning how to design circuit boards. At the time there were still a lot of international companies manufacturing computer hardware in Ireland. He got a job in the production department, often working 12-hour shifts. After 2008 the industry went into decline and he shifted employment to a German circuit-board manufacturer. They sent him to their factory in South Africa, where he was given a managerial position in one of the departments. He came to the UK in the mid-2010s and got the job in the 3D printer department – partly helping with the development, partly with supervisory work (planning, work allocation, training), quality control, but also direct assembly work.

V. grew up in Kenya and Gujarat. His family got the money together to send him to the UK in his early 20s, to study engineering in Manchester – paying £28,000 study fees upfront. He had internships at Honda and an aerospace company, while working low-paid jobs in fast-food and retail. He got the job in the 3D printer company after he graduated, they used his CAD knowledge and engineering skills while paying him the minimum wage. To prop up his income he has a second job as a shop-floor worker in retail. He works seven days a week. When I joined, they employed another post-graduate of Indian background, who had worked internships in oil and gas companies. He left shortly after to try and set up an App development business with his university mates.

S. grew up in Lebanon, where he had studied and migrated to the UK in the early 1990s. He had various jobs before becoming a supply-chain manager for an American apparel company based in London. He then shifted to the company, where he helped develop the ink cartridge filling machines. In the 3D department he is mainly involved in development and maintaining relationships with the suppliers.

T. was born in the UK, his father came from Greece. He was an apprentice for an alarm-system installation company, then shifted to a company engaged in testing and certifying of electrical appliances. He started to assemble and experiment with 3D printers ‘as a hobby’. He was hired as the main developer for the 3D printer project. A proper self-taught tech-nerd. The company got into major difficulties when he left the job, being the most experienced (and interested) in 3D printing. He left the company in order to start a business with a friend: producing large-scale 3D printers to print mannequins using the measurements of clients. Tailors can use the mannequins to fabricate custom-made garments, without having to bother their rich customers.

M. was born in Argentina. He went to a technical college, learning basic mechanical skills. He then worked in a tobacco mill, maintaining the huge cutting, mixing and drying machinery. Early on he experimented building his own machines. When he came to the UK he started building and selling machines that can digitalise video 8 films. He started at the company in order to have a more stable income.

These colleagues were the intellectual backbone of the department. In addition there was a small software team, which dealt with the touch-screen program and the web-cam appliance. In the ink department the company employed workers of similar background for the development of the machinery: workers mainly from Northern Africa and Bangladesh who experimented with centrifugal machines (to empty the cartridges from old ink), washing machines, de-capping machines and re-filling pumps. These workers were in a constant battle with the main cartridge manufacturers which try to prevent re-filling by all means necessary: from electronic chips, which have to be re-programmed to internal valve-systems, which destroy the cartridge if the wrong kind of re-filling pressure is used. Most of these invented machines looked pretty ramshackle, some of them had serious health and safety issues, but they were unique – developed by low paid workers gathering experiences directly from the shop floor and using them in experiments in under-funded and under-equipped workshops. While these ‘technical workers’ were all male, the production workers were mainly, though not exclusively female. Most of them came from Gujarat and Goa, some from Iran, Hungary and Lithuania.

*** The 3D printer supply chain

Most of the printer parts arrived in pretty basic form, others as pre-fabricated modules. It is worth noting that those parts whose production involves the most expensive machinery came from Eastern Europe or China, while most of the labour intensive work was actually done by us in London (and ironically, the first sold Paranoid printer was delivered to a company in Hong Kong). To give some examples:

* Cables

Cables arrived on reels, manufactured mainly in the UK. Heat shrink arrived from Germany; connectors and switches came from East Asia and capacitors from El Salvador. We have to cut cables to size, attach connectors by crimping or soldering. A single printer needs around a dozen different internal cables. It takes about 1.5 hours to produce a whole cable set, done in batches of 20.

* Fans and Motors

Both electronic fans and motors come from China. Their cables have to be cut to size and connectors have to be attached. It takes about 45 minutes to prepare fans and motors, again, once it is done in bigger batches.

* Bearing blocks, rods, extruder plates, inner metal frame, outer plastic parts

Most precision metal parts came from a UK company’s plant based in Slovakia, while the inner metal frame and outer plastic parts came from China. The manufacturing of these parts require precision CNC machines and larger plastic injection moulding machinery. We had to glue the bearings into the bearing blocks, the inner frame had to be riveted together, the outer case connected with screws, nuts and bolts.

* Electronic boards, LCD and webcam

All these parts came ready-made from China. We had to solder single capacitors onto circuit boards for adjustment, assemble a frame for the LCD and re-work a plastic hinge in order to accommodate the cables for the webcam – which had been added as an extra-feature to the original model. To re-work a single hinge (drilling, cutting inner plastic ribs, preparing cable, glueing) alone takes 20 minutes.

It is surprisingly easy to order standard electronic/electrical components such as motors, fans, connectors and cables online from around the globe. Internet commerce and global logistics make it possible for even small manufacturers to have a global supply chain. SAP or other stock-taking software makes it fairly easy to get an overview of current stock and requirements for re-ordering. The flip-side is that these are standard parts, meaning, extra work has to be done to them in order to fit them in properly.

The printers’ main parts were custom-made. The big plastic parts (door, hinges etc.) were ordered in bulk from China in order to lower costs. The mechanical metal parts came from Slovakia. When changes were required it was not enough to just send technical drawings to eastern Europe or to speak on Skype. Guys from the development department had to travel to Slovakia twice in half a year to discuss production and quality details with the supplier. When the supplier in Slovakia increased the price for metal coating a local company had to be found: we drove metal parts from Park Royal to a small backyard work-shop in Surbiton, south London, where guys spray painted and coated stuff under pretty third-world-ish conditions. Similar problems of global cooperation occurred with the web-cam. A cheap supplier was found in China, but the mobile phone app, which had been developed by the software team of the 3D printer company, had difficulties communicating with the camera. A fair amount of emails were sent back and forth, seemingly with the help of google translate. Talking about translation, the translations of the 3D printer manuals into French, Spanish, German and Dutch were done by a guy in Switzerland, who also cooperated with the software department. They were pretty bad and needed re-working. While it seems easy to establish a supply chain of standard parts, things look different for elaborate manufacturing.

Three times in 9 months crucial parts ran out and production stopped. In one case it was due to under-capacities of a metal parts supplier, in another case a combination of wrong stock-taking of motors and the fact that a delivery of an extra order from China can take up to two, three weeks. This also happened with the Chinese heat-element – a fairly standard £3 electronic part. Although other heat-elements are on the market, according to a colleague in the development team it would not have been possible to use them without making major changes due to both material dimensions (length of wires etc.) and heat dynamics which impact on the printing process. Another case of stock depletion was due to the London company not having paid their last order on time. This problem of not paying suppliers on time seemed to have been fairly common in the ink cartridge department, too.

So why not just 3D print your 3D printer parts?

According to the utopian vision, the easiest would be to let the 3D printer print their offspring themselves – the supply chain problem and problem of technical changes would be solved, wouldn’t it? As already indicated, both technical and financial aspects limit the use of 3D-printed parts. We actually used 7 different 3D-printed plastic parts for the production of the printers. Largely, these were parts that were added on during technical changes, e.g. a small plastic frame for an electronic fan whose position had to be changed slightly. These parts were small (4cm x 4cm maximum) in order to be able to print several pieces at the same time on a single printer platform (25cm x 25 cm). While these 3D-printed parts could be used for ‘lighter duties’, an attempt to use 3D-printed parts to replace the metal bearing houses (whose quality/imprecision caused frequent problems and extra-work) failed: being situated to close to the motors and heat element of the extruder nozzle, the 3D-printed plastic became too soft and the whole structure started to wobble. But apart from size and technical limitations, the main obstacle to using 3D printers as machines was time and costs.

A single production printer can print roughly 6 pieces of the same part in 3 hours. At a production volume of 3 manufactured 3D printers per day and 7 different parts required per printer, around 20 printed parts are needed. A single printer would need to run around 8 hours a day – this doesn’t count the time it needs to change the filament, take out the printed parts, put a new Z-sheet on, check the quality of the printed parts, switch software over to different type of part etc. When two printers were running for production it was pretty much a part-time job to monitor them, re-set them, check the parts etc. Even when calculated at 2 hours of human input for the production of the needed 20 parts, this would still amount to a labour cost of roughly £1 for a mediocre small plastic part, not taking into account machine costs (£2000 for the two printers), material costs (£20 to £30 for 750g of filament) and the time needed to create the initial computer design (roughly 8 hours per part). And as a side-note referring to the question of the potential of 3D printing to abolish the division of labour: the person who runs between printers and operates them doesn’t have to know anything about how to create a CAD image. There was no different quality required to operate the 3D printers from other ‘part producing’ machines.

*** The 3D printer cost calculation

Perhaps because of the small production volume of 20 printers a week and therefore small order volumes for parts, material costs are quite high. So are the hidden labour/production costs apart from the direct labour costs for assembly work. The cost calculation is roughly as follows:

* Material cost: around £500 (most expensive parts being custom-made metal parts, electronic boards, LCD screen, web-cam)

* Direct production cost: £200 (assembly work, testing, packaging – around 16 hours per printer)

* Indirect production cost: £100 (advertisement, accountant, maintenance)

* Sales price to retailers (Staples): £800

* Retail price: £1,400

Management hoped to break even on the sales of the 3D printers and to make money with the sale of Paranoid print filaments. The filament was bought from a company in Czech Republic for £20, then labelled with a Paranoid label and put on the market for £70. A reviewer of the 3D printer said: “[Paranoid]’s justification for the filament pricing runs beyond the chip embedded in the casing, though. Apparently, the filament has been specifically designed for the [Paranoid] printers, using high-quality virgin material with a tolerance in filament diameter is just 0.01mm throughout its length to ensure smooth running.” The irony here being that the company tried to enforce in the 3D department what they tried to circumvent in the 2D ink refilling department: an exorbitantly high price for the use of ‘original’ printer cartridges.

*** The 3D printer production process

Initially a smaller team of four workers each assembled a complete printer themselves. In order to make it easier to quantify and measure each work step and to train newly hired people quickly, the work was divided up. The assembly process involving six workers looked like this:

* Worker 1: Cutting and assembling cables, fans, motors in batches of 20, soldering capacitors on electronic parts, assembling LCD frames etc.

* Worker 2: Assembling sub-assemblies of the X- and Z-axis

* Worker 3: Assembling the extruder sub-assembly, maximum 5 extruders a day

* Worker 4: Complete wiring and assembly of inner-core of printer (axis, extruder), calibration

* Worker 5: Riveting of the frame, packaging

* Worker 6: Assembly of the outer chassis, door etc.

The whole sub-assembly/preparation of the printer components (cable-set, extruder and axis, inner-frame etc.) takes about eight hours. The printer modules have to be assembled (axis put into frame, internal wiring, outer shell), which takes about five hours. There are additional work steps (calibration, testing and packaging) required. The total production/assembly time per printer from single screws, connectors etc. to a completely packaged product is about 16 hours. In addition to the six workers directly involved in assembly work there were three workers employed for quality control, team leading and ‘research and development’. There was one assembly department manager and one 3D project general manager. In the office and warehouse there were three people employed in the software/media department, two for ordering of parts and in the warehouse and two accountants (who also worked for the ink department).

The main problems the departments had in terms of profitable production of 3D printers were as follows:

* low productivity/too high production costs in the assembly department

* unexpected amount of re-work and ‘research’ work due to technical problems

* frustration of core workers due to low wages, hierarchies and general ‘unviability’ of the project

* increasing market pressure

Given the relatively small series of three to four printers produced per day there was also only limited scope in investing in ‘time-saving’ machines for the assembly process. For example, we measured and cut all cables manually, while it is fairly common in manufacturing to have machines doing this. Similarly when it comes to screwing operations – I worked at a Nokia mobile phone factory, where they had ‘screwing stations’. You only had to insert the part and press a button. Here we had to select the right screws and use a traditional screwdriver. The guys from development looked into outsourcing the most simple operations, such as cable assembly. According to them a 200cm 26-ribbon cable, cut at the right length, with two connectors attached and tested would cost £2.60, including transport. It would take us around 6 minutes to fabricate a single cable – which was still comparably cheaper.

*** Production from a worker’s point of view

I started working in the department during the ‘developmental’ phase, meaning, I was trained to do a complete assembly of the printer initially, then mainly doing the sub-assembly. The team being relatively small us ‘assembly operatives’ were still in close contact with the guys in development, so we heard a lot about the various technical difficulties and were more included in the problem-solving. That in itself was pretty enjoyable work, even if you are not majorly interested in 3D printers.

At this point the development largely depended on two, three workers who knew more about the whole issue, while the department manager was mainly engaged with coordination (ordering of material, stock taking, production requirements) and planning the layout of the production process. He had no major technical knowledge. Once they deemed the converted Paranoid printer fit for purpose, two new workers were hired for the assembly operation. From then on, the division of labour between different assembly operations and between assembly and development department became more formal and rigid.

The two new guys were only trained to do either cable manufacturing and soldering or assembly of the extruder. The manager asked us to put up a big white-board and write down all the individual assembly steps, the skills required, the names of workers with their skills, the time it takes to perform each individual work-step. The calculation of the time needed per work-step was made by a colleague who had worked in assembly and was now employed as team leader and quality controller. Because we all got on we kept some margins of breathing space in the calculated times. The manager tried to detect this breathing space either by standing behind a worker and actually timing them – though he didn’t have much time to do this frequently. The other way was to let different workers perform the same assembly process and see if there were differences in outcome. Finally he gave one worker the order to e.g. produce five extruders in a day, which meant staying for overtime. The manager probably thought that workers would speed up a bit, in order to not get home too late. We talked amongst each other about this and largely managed not to stress ourselves out.

Once regular production started there was less scope for the assembly operatives to take part in the ‘development’ aspect. When the manager called the three guys responsible for development together, we called it the ‘magic circle’. The technical problems emerging were quite substantial and being less involved in the development aspect meant that having to re-work printers and parts became more frustrating. The printers had problems with electro-magnetic fields: having electrical wires and metal parts moving back and force in a metal frame created these fields, which then impacted on the electronics and software program. We had to dis-assemble many printers and re-wire most of the parts. At this point the main ‘tech nerd’ left the company to become self-employed, which gave something like a final blow to the project.

The ‘tech nerd’ leaving was expression of a wider frustration:

* It was clear that the company would try to make us assemble this printer on minimum wages. The only ‘official’ chance to get a wage increase would be to become a team leader – out of four assembly workers only one could become team leader. You would then be paid £17,000 p.a. Our income contrasted starkly with what we perceived as the income of the upper managers and the owner’s income. While we were told that the company was ‘running badly’, the upper managers parked new Maseratis, Bentleys and BMWs in front of the factory. The 3D project manager only appeared once in a while, she seemed mainly busy with presenting the 3D printer at industrial fairs in Las Vegas or other places. The owner of the factory turned up every second week, a dandy-type with a whippet dog, driving vintage Jaguars and new Bentley SUVs. Workers resented this display of wealth, at the same time, being mainly unskilled (female – in the case of the ink department) migrant workers, they bowed to the English ex-entrepreneur, who was now mainly busy with his real estate business, his private jet and ranch in the US.

* We all sensed that due to under-investment, mis-management and general market pressure, ‘our’ product would never be competitive. On one hand we would not have to bother about this too much, as long as we were paid. But it is somehow frustrating to know that other teams in other small enterprises around the globe had probably faced the same technical difficulties and found solutions, so in a way most of our development and re-work work was a waste of time. To us, the printer looked like an overweight fax-machine, technologically about to be obsolete. Compared to products from HP, Epson or others, their productivity would probably be 30 times higher and quality way better.

* This general frustration was given further small blows by pretty arbitrary management decisions, such as the sacking of a quality controller with little notice (as part of a ‘business requirement process’) or sending the whole factory on short-time work for two weeks and then asking the 3D department to work overtime during the following weeks.

I will describe our attempts to deal with these frustrations collectively later on.

*** Worker’s discussions

The good thing about being a small team of workers who sit or stand around a table cutting cables or assembling parts is that you have plenty of opportunity to shoot the breeze about a wide range of topics. While we were working in our dingy workshop, the world around us was changing rapidly: war in Syria, refugee crisis, Brexit referendum, terrorist attacks, signs of decay of the establishment. Our discussions were informed by the varied background of their participants: one friend, a devout Muslim, born in Pakistan and raised in London, who had worked in all sorts of industries and even in the top-notch Ocado warehouse; another friend born in Algeria, who had witnessed the civil war, worked on construction and in warehouses in the UK, married to an English woman; a friend from Hungary, who had lived in the UK for 17 odd years, worked in the company for nearly 10 years, very much a Hungarian nationalist and Brexit supporter (he had obtained his English citizenship); an Irishman, Hindus, Arsenal fans, Kiss FM listeners, all sorts.

Apart from discussing the contradictions of small-scale capitalist production, we talked big politics. Although being (second generation) migrants, those of the colleagues who could vote, voted for Leave. Only one worker (a second generation Ugandan Gujarati) said he did so because ‘all the migrants come in to take benefits’ (his girlfriend was Lithuanian and worked in the factory), the others said it was ‘two fingers to the elite’. They might have been right, because the day after the referendum, the main manager came in crying about the fact that importing the parts from China and other places will now become much more expensive – he was worrying about future access to export markets, too. The colleague from Hungary usually wore a t-shirt saying “Love Europe – Leave the EU”. He was very concerned about the ‘refugees’ and the potential ‘danger’ they posed to national security. We pointed out that he himself is a migrant, but he replied that he was welcomed, that he had legal papers and that he would leave if he wasn’t. This was during the attacks on the two Polish blokes, shortly after the Leave vote. He followed the Hungarian news and consequently he was quite obsessed with ‘the refugees’ – but luckily enough there were quite a few refugees in the department: the colleagues from Algeria and Lebanon could put things into a clearer perspective, though this might not have reached the ‘emotional element’ of his rather schizophrenic nationalism. The second generation Ugandan-Gujarati (Chamar caste, Dalits or so-called Untouchables, who made jokes about the other Kenyan Hindu colleague, who was a frequent temple-goer) was unsurprisingly quite anti-refugee – the refugees being mainly Muslims. It didn’t help too much to point out that his parents had been refugees in a major refugee crisis and had been welcomed by pretty nasty UK fascist mobilisations. At the same time he was pretty ‘race conscious’, identifying mainly with Black culture and music and talking “this is Whitey stuff, that is Whitey stuff”. In the end we all agreed that ‘the system is fucked’, but we might not have been so sure about what the system is. The ‘devout Muslim’ friend was a Corbyn supporter, because Corbyn was against the Iraq war and for social justice. The colleague was clearly against the bosses and injustice, but in the end it was literally all a Zionist conspiracy – from archeological and evolutionary science to the creation of ISIS. He believed that the rulers can influence our brainwaves and that they had made the fascist pig kill Jo Cox. Allah had given us money and instructions of how to deal with it fairly. Our discussions travelled far in time and space, talking loads about religion, spirituality, the universe and cosmic energy – but then we found ourselves back under the neon-strip lights, being paid badly for assembling 3D printers that didn’t sell.

*** Disputes, lunch meetings and wage demand

The first open dispute happened in the ink department. All workers on old contracts (signed two years ago or earlier) were called to sign a new contract allowing the company to announce short-time work without wage compensation with 24-hours prior notice. We heard that a bigger group of 20 to 30 workers refused to sign the new contracts. They were called into the canteen and told that even if they would not sign this wouldn’t make a difference. There is not much communication possibility with workers in the ink department, you see each other briefly in the canteen or at the clock-in machine, so it was difficult to know more about it all. There was also a rumour that a handful of male workers from the ink department, mainly team-leaders, had joined a union. This was after the minimum wage increase (from £6.70 to £7.20), which left them earning as much as ‘an unskilled woman who just walked in off the street’. Six months previous, the main manager had promised that after the minimum wage increase ‘the pay difference would be retained’, which would have meant a pay increase for the ‘senior workers’ – now he went back on his word and announced the prospect of short-time work, plus redundancies for five workers in the goods-in department. Although it was difficult to verify all this at the time, it was good to know that there were some rumblings.

Us five assembly workers without ‘supervisory positions’ then decided to meet for lunch and discuss how to raise a demand for a wage increase. This happened just after a woman worker they wanted to hire for assembly (she had worked at Bosch in Hungary and at a local ready-meal factory, where some comrades of our collective work) had quit after just one day because she felt the work was ‘too complex’. Two other candidates didn’t even turn up for the final interview. We discussed that our main argument would be that only a higher wage would guarantee ‘staff and knowledge retention and stability in the team’. The discussion went more or less like this:

– “We once went to the manager before and asked for more pay. He promised something for the future, but nothing came out of it. When we brought the issue up again he said that he can’t do anything and whoever wants to leave can leave”.

– “They say that the company has no money, but then they turn up with new cars every month.”

– “We shouldn’t mention that, that’s not really any of our business.”

– “In any case, they would have difficulties if two of us actually would leave. It would take them at least one month to re-train new people”.

– “But then this is my first job after my engineering studies. I need a good reference.”

– “I, on the other hand, don’t give a shit. I plan to leave in six months anyway.”

– “We should find good arguments for our claim nevertheless. Why should we be paid the same as the women in packaging or ink department who do easy unskilled work? We produce an expensive good”.

– “It doesn’t matter what work you do, your bills are the same, you have to eat. So why make a difference between us? We should get in touch with some people in the ink department and invite them for lunch, too.”

– “That would cause a big fuss if management finds out. We should keep it on the 3D printer department level.”

– “But they will immediately play us off against each other. They will tell all the folks in the ink department: ‘Look at these 3D people, they want more money, although the 3D department has made no profits at all, all investment was transferred from ink.’ They have their own problems at the moment. If we can get a dozen out of the 150 on board we could join a union and put forward a more official wage demand.”

– “That might be so, but look at the people in the ink department, most of them won’t do nothing. They are unskilled women in their 50s, who hardly speak English. They are happy to have a job”.

– “The main pressure we have if they don’t pay us more is to refuse overtime and work slower, refuse the new productivity target.”

We decided to draft a letter and sign it, asking for an increase of £2,000 p.a., and hand it over as soon as the 3-months contracts of two of us were renewed ten days later. The problem was that the week after our lunch meeting management announced short-time work for all workers, including our department. We were on four hours a day. The short-time work lasted for four weeks, interrupted by one full-time day each week. Management tried to avoid sending people home for a longer period, because people might become eligible for redundancy payment. At least three younger male workers from Goa employed in the ink department left around that time. Two found jobs at Honda in Swindon, one a better paid retail job.

We said that we would put forward the letter as soon as production was running properly again. Unfortunately it turned out that management had decided to fold the 3D production. Some of us were sent to work in the ink department, one worker from the development department was fired and the rest were told to turn the remaining stock into sellable printers, now being sold for £800 instead of the planned £1,400. We were somehow left feeling that the whole show was either extremely badly calculated in the first place or the whole enterprise was mainly a way to keep a semi-bankrupt company ticking over for tax and financial reasons, while the profits that had been siphoned off earlier on were now invested elsewhere. It became known that the company had a major dispute with the tax office (HMRC) and had to pay back several million pounds. At the same time the company lost a contract with a major distributor (Cartridge Save) and announced the redundancies of a further 14 people, “to eliminate certain methods and tasks that are now deemed non-vital to the business’s trading” (management letter).

*** Work in the ink cartridge department

They sent us off to work in the ink department and I didn’t mind working there – meeting new people, learning something new. Workers were very interested in how things were going with 3D, but most of them quickly added: “the company put so much money into that project, it’s now all wasted”. In the ink department, as mentioned, production volumes had come down significantly during the last five, six years – from 15,000 per day to now 10,000 on a busy day. Around 100 workers were directly employed in the process. Although officially the process will be categorised as recycling – we are actually talking about manufacturing, given that many of the cartridges have to be ‘converted’ and some of their capacity enlarged during the process. The original manufacturers often artificially limit the amount of ink per cartridge. By breaking out an inner plastic division and sponge-element, more ink can be filled. The process is more complex than it seems: it is not easy to empty the cartridges, powerful centrifuges are needed; you cannot clean the cartridges with normal water, as minerals will spoil the ink; a certain pressure has to be used for the re-filling, otherwise things get messy etc. All this makes the production process fairly elaborate and the division of labour more minute:

* sorting ink cartridges

* taking off stickers, external cleaning

* internal cleaning

* centrifuge

* conversion

* re-filling

* testing

* marking for label

* re-labelling

* packaging